Building a Springbok

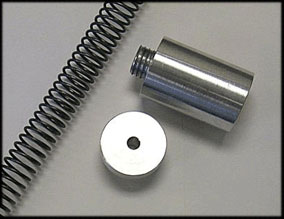

To make a springbok, simply attach two masses to opposite ends of a spring [Figure 1]. A guide-pole and base are needed to maintain stable vertical motion [Figure 2]. The masses we used in our 'boks are made of aluminum, as are the guide poles. Other materials can be used; just keep in mind that it is best to reduce the friction force between the two masses and the pole as much as possible.

To make a springbok, simply attach two masses to opposite ends of a spring [Figure 1]. A guide-pole and base are needed to maintain stable vertical motion [Figure 2]. The masses we used in our 'boks are made of aluminum, as are the guide poles. Other materials can be used; just keep in mind that it is best to reduce the friction force between the two masses and the pole as much as possible.

To insure that the masses stay attached to the spring, machine a set of threads on each mass so that the spring can be "screwed" into place. Drill a hole through the center of the two masses so that they can slide along the pole.

Specifications

A 'bok can be made in different sizes:

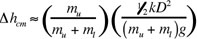

When used as a demonstration, make sure that the 'bok jumps to a satisfactory height when the larger mass is on top. One can estimate how high a 'bok will jump (assuming it is made with a light, stiff spring) by using the following relationship:

Be sure to select the ratio of the two masses so that the difference in the "jump height" for the two orientations of your 'bok (i.e., larger mass on top versus smaller mass on top) will be obvious. For a sufficiently stiff spring, the jump height is proportional to the upper mass, so the ratio of the jump heights is equal to the ratio of the two masses. We have used mass ratios as high as 9 to 1.

There are two other design issues to keep in mind when building a 'bok:

- Once a spring is selected, the only way to increase the jump height of the Springbok is to decrease its total mass. However, if you decrease the two masses too much, the spring mass will be comparable to one or both of the masses. If this is the case, a simple Hooke's Law model that ignores the mass of the spring will not provide an accurate description of your springbok system. To avoid this problem, start the building process by selecting a stiff lightweight spring. Then choose masses accordingly.

- The only other significant design issue is damping in the spring. Good agreement with a simple Hooke's Law model requires a spring with a small damping coefficient. Using a model that accounts for damping may be necessary to achieve good agreement between model predictions and data.

The two springboks used in the "QuickTime Clips" have the following specifications:

| large 'bok | tiny 'bok | ||

| masses (g) | |||

| small mass | 93.8 | 60.5 | |

| large mass | 240. | 275. | |

| spring | 59.0 | 70.0 | |

| elastic constants (N/m) | |||

| average value | 359. | 458. | |

| uncertainty | 15. | 13. | |

Damping coefficients for the two springs can be determined from "Quicktime Clips" of the masses oscillating while the 'bok is held fixed to a tabletop.

Cleaning and Lubricating

Sliding friction will decrease the performance of a 'bok, so you may wish to take steps to reduce it. Beyond making all contact surfaces as smooth as possible, you should clean and lubricate them. For our 'bok, which was made out of aluminum, we used a lacquer thinner to clean surfaces and graphite to lubricate them. We have also used silicone spray to both clean and lubricate.